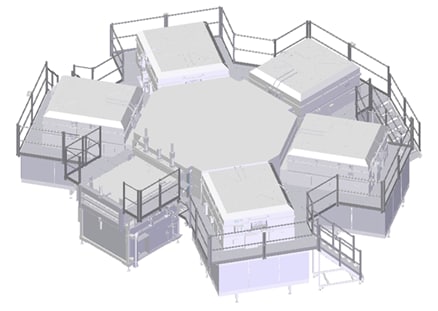

Tokyo Electron (TEL) has recently unveiled its latest innovation, the Betelex™2700 PICP™ EX Plus plasma etch system. Designed to cater to the growing demand for high-resolution displays made from 8.7th generation glass substrates, this cutting-edge system promises to deliver enhanced process capabilities and improved production management in the field of etch technology.

Displays made from 8.7th generation glass substrates, predominantly used in IT products featuring OLED panels, require advanced etch technologies that offer greater uniformity, selectivity, and effective corrosion reduction. Recognizing the need to meet these requirements, TEL has developed the PICP EX Plus plasma module, specifically designed for the 8.7th generation display segment.

The PICP EX Plus module combines TEL's proprietary PICP high-density plasma source with enhanced control of plasma distribution and temperature. This integration enhances the precision and performance of the etch process, allowing for the processing of more diverse device structures. As a result, the PICP EX Plus module offers higher production stability, improved yield, and lower running costs.

In addition to the PICP EX Plus, TEL has also announced the release of APX, a new module designed to control corrosion. By utilizing TEL's unique corrosion control method, APX effectively addresses the issue of residual etch gas causing aluminum corrosion during the aluminum etch process. APX not only helps improve yield and lower running costs but also enables superior environmental performance, thereby boosting overall productivity.

Takeo Kaeriyama, General Manager of the Display Business Unit at TEL, emphasized the significance of the PICP EX Plus and APX modules in meeting the evolving needs of the industry. He stated, "As the interest in the new breed of displays continues to rise, we have developed the PICP EX Plus and APX modules to meet our customers' demands for the next generation of technologies. These products offer superior etch performance, high production stability, and improved yield, contributing to our customers' manufacture of advanced displays."

With the launch of the Betelex™2700 PICP™ EX Plus system and the APX module, Tokyo Electron is poised to make a significant impact on the plasma etch technology market. These new additions not only enable the production of large displays with high resolution and added value but also help achieve higher production stability, improved yield, and lower running costs. It demonstrates TEL's commitment to developing cutting-edge solutions that cater to the evolving needs of the display manufacturing industry.