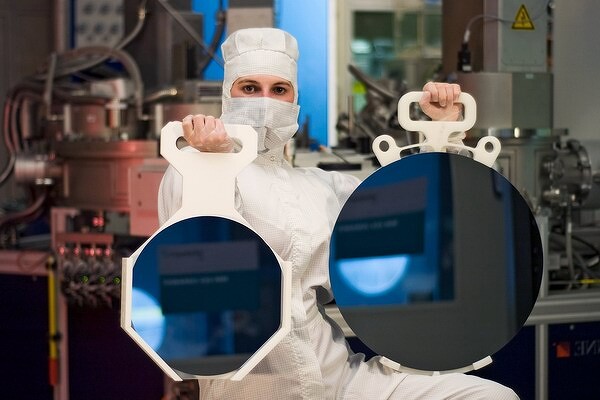

The largest wafers used to produce chips in the semiconductor industry are 300mm (12 inches) in diameter, 200mm being the industry standard. The diameter has increased from 100mm (4 inches) in the 70-s to 150mm (6 inches) in the early 1990-s to improve throughput and reduce chip cost as it allows for more chips to be produced per wafer with the same number of operations.

A group of companies including Intel, TSMC, Samsung, IBM, and GlobalFoundries formed a partnership called the Global 450mm Consortium (G450C) to develop the fab equipment and tools required to manufacture 450mm wafers. However in the late 2010-s the big companies could not transit from 300mm wafer as the technology was not there yet and the transition cost was immence, as well as the investments they had made into the 300mm fabs. Estimation done by the companies showed that the investment needed for a 450mm fab could break a USD10 billion barrier, compared USD5 billion required for 300mm wafer fab.

Initially TSMC was keen on transition to 450mm wafers, as it would give them cometetive advantage to their rivals, UMC and SMIC, and even had a 5-year plan to build its first 450mm fab. But after a while the management of TSMC realized that by adopting 450mm wafers they would step onto Intel's and Samsung's territory and there would be a hard competition with the "big fish" companies. The fear was that Intel and Samsung both had more technical and financial resources than TSMC and could invest more of their resources into this technology. After a series of meetings with the board and management, the decision that this move should not be supported was made.

The only thing that remained was the excuse that needed to be made to reject support of transition to 450mm wafers, and that was not a difficult thing to do. TSMC declaired that they would focus on advanced technology and processes development, not the wafer size. It might be exactly that this decision let TSMC be what they are now in the world of foundry business- the undisputed leader.