At its 2021 Investor Meeting, Applied Materials unveiled plans to grow the company’s revenue, earnings and free cash flow by enabling customers to accelerate improvements in chip power, performance, area, cost and time to market (PPACt). Applied also announced plans to generate 70% of future services and parts revenue through subscription-like long-term agreements.

Applied outlined five major inflections that are fueling secular growth and the need for innovation as the company drives its longer-term strategy.

At a macro level, the digital transformation of the global economy is accelerating. In computing, AI workloads are fueling the need for new architectures based on entirely new types of silicon.

Within chipmaking, traditional Moore's Law 2D scaling is slowing, creating the need for a “new playbook” for PPACt that enables continued chip- and system-level improvements. Another inflection is the need to grow the industry more sustainably and equitably.

Finally, customers are seeking not just better products, but also better outcomes, resulting in a business model shift to solutions delivered via subscription models.

“The core of our strategy is to be the PPACt enablement company,” said Gary Dickerson, president and CEO of Applied Materials. “Our broad portfolio and ability to combine technologies in ways no other company can be accelerating value creation for our customers and puts Applied in a leadership position to advance the state of chipmaking for years to come.”

Applied has aligned its strategy to meet the increasingly complex needs of its customers, many of whom participated in the event to discuss trends in computing, semiconductor technology, services and ESG (environmental, social and governance).

Applied summarized the evolution of its Semiconductor Systems business. The portfolio is expanding from unit process equipment that performs a single step to include co-optimized systems with pre-proven combinations along with Integrated Materials Solutions where multiple process technologies are combined under vacuum to create novel materials and chip structures that are not otherwise possible.

“It has been a great journey to walk with Applied Materials over the past 30 years,” said Dr. Mark Liu, chairman of TSMC. “Beyond 3nm, to sustain the rate of improvement, and I believe we will, we need to work together closer than ever before. We need to innovate in new transistor structures, in new materials, in new system architecture, and new 3D integration. It is an exciting time. We look forward to working with Applied Materials to discover the future semiconductor innovations.”

The company also presented case studies of Applied AIX (Actionable Insight Accelerator) – a new platform that enables semiconductor engineers to use the power of big data and AI to accelerate the discovery, development and commercial deployment of new chip technologies.

“It’s hard to simply put a number on it, but we all know that improving the process margin is the key to enable technology node migration,” said Seok-Hee Lee, CEO and president of SK hynix. “In many cases, it not only requires the adoption of advanced new technologies in a number of areas including materials, process and equipment, but it also requires all those factors to be optimized for the integration of multiple process steps. Each change in process variables affects others at multiple levels, so accelerating the cycle of learning to come up with the optimal solution is crucial. If Applied Materials develops new process technologies which are already co-optimized with adjacent process steps, it will help reduce development complexity for chipmakers. I think our development activities can move at a fast pace if we work together to harness the power of sensors, big data and AI to map and predict the effect of many process variables.”

As electronic products become smarter the silicon content per device is increasing, including specialty semiconductors based on mature process nodes. Applied is addressing this growing demand with its ICAPS group (IoT, Communications, Automotive, Power and Sensors).

The company is now generating more than $3 billion per year in the ICAPS business.

“GF is focused on the largest, most pervasive segments of the semiconductor industry and where technology has the broadest impact,” said Tom Caulfield, CEO of GF. “Our industry began a fundamental shift 15 years ago with the emergence of the smartphone, which brought new features including image sensors, battery management and secure pay. This also led to the Internet of Things that is now moving from all things connected to all things intelligent. Gary Dickerson and the team saw this trend early on and created a group dedicated to innovation on adding features to semiconductor products on all nodes. Today at GF, we leverage much of Applied’s capabilities for the technologies we innovate and manufacture.”

To support the sustainable growth of the semiconductor industry, Applied underscored its ESG commitments with initiatives that are being driven within the company and in collaboration with suppliers, customers and the computing industry.

“Micron is highly committed to reducing our environmental impact,” said Sanjay Mehrotra, president and CEO of Micron. “We appreciate how Applied Materials has embraced similar goals and made strong commitments to increasing the eco-efficiency of its manufacturing systems.”

2024 Financial Model

In the base case assumptions of its 2024 financial model, Applied plans to grow revenue by over 55% and non-GAAP EPS by more than 100% as compared to fiscal 2020.

It plans to increase Semiconductor Systems revenue by over 60%. The company announced a commitment to return between 80 and 100% of free cash flow to shareholders.

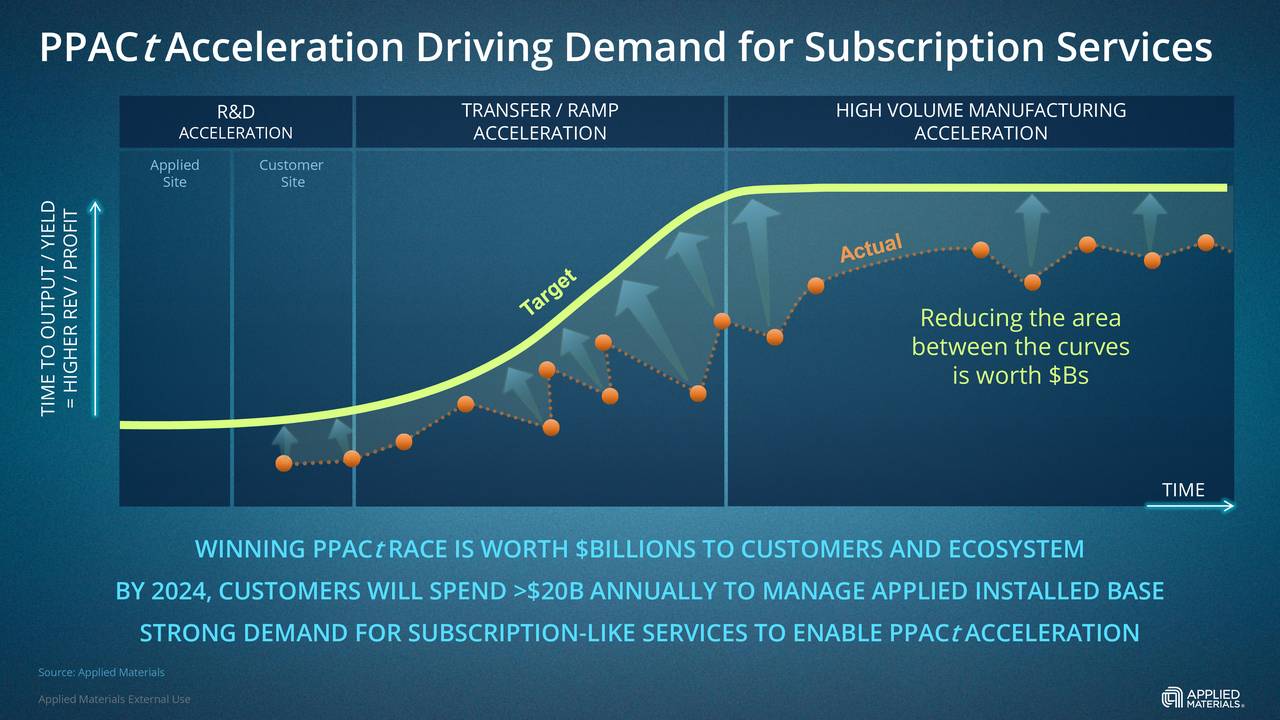

Applied plans to grow its services business by over 45 percent as it increasingly moves beyond transactional parts and maintenance to comprehensive services delivered via subscription to give customers better outcomes from lab to fab. The key to the growth strategy is expanding the use of digital services and remote capabilities that use sensors, analytics and AI.

In its Display business, Applied expects to benefit from the next wave of OLED growth as the technology becomes more pervasive in smartphones, notebook PCs, tablets and TVs. Applied plans to increase annual operating margin in its Display business to around $600 million on average over the four years ending 2024.

“The growth momentum in our reporting segments is the foundation of our new target financial model,” said Dan Durn, senior VP and CFO of Applied Materials. “Combined with our focus on execution, discipline and resulting margin improvements, we plan to drive a high-ROI model that generates strong free cash flow and attractive shareholder returns.”