In the continually advancing field of optoelectronics and photonics, precision and reliability in assembly processes are not merely goals—they're imperatives. Tresky GmbH stands at the forefront of this field, consistently pushing the boundaries of innovation, particularly in the niche of sub-micron bonding technology. At the productronica 2023 event, Tresky made a significant impact by revealing its latest advancement: the formic acid module. This development is poised to set a new standard in the efficiency and reliability of bonding processes.

The formic acid module, a brainchild of Tresky's R&D team, cements the company's commitment to excellence. According to Tresky's Managing Director Daniel Schultze, the utilization of formic acid as a reducing agent catalyzes the creation of oxide-free surfaces that are well-wettable, establishing pristine conditions necessary for high-precision soldering tasks. Environments that demand such meticulous processes, notably in optoelectronics, typically preclude the use of conventional fluxes due to stringent purity requirements.

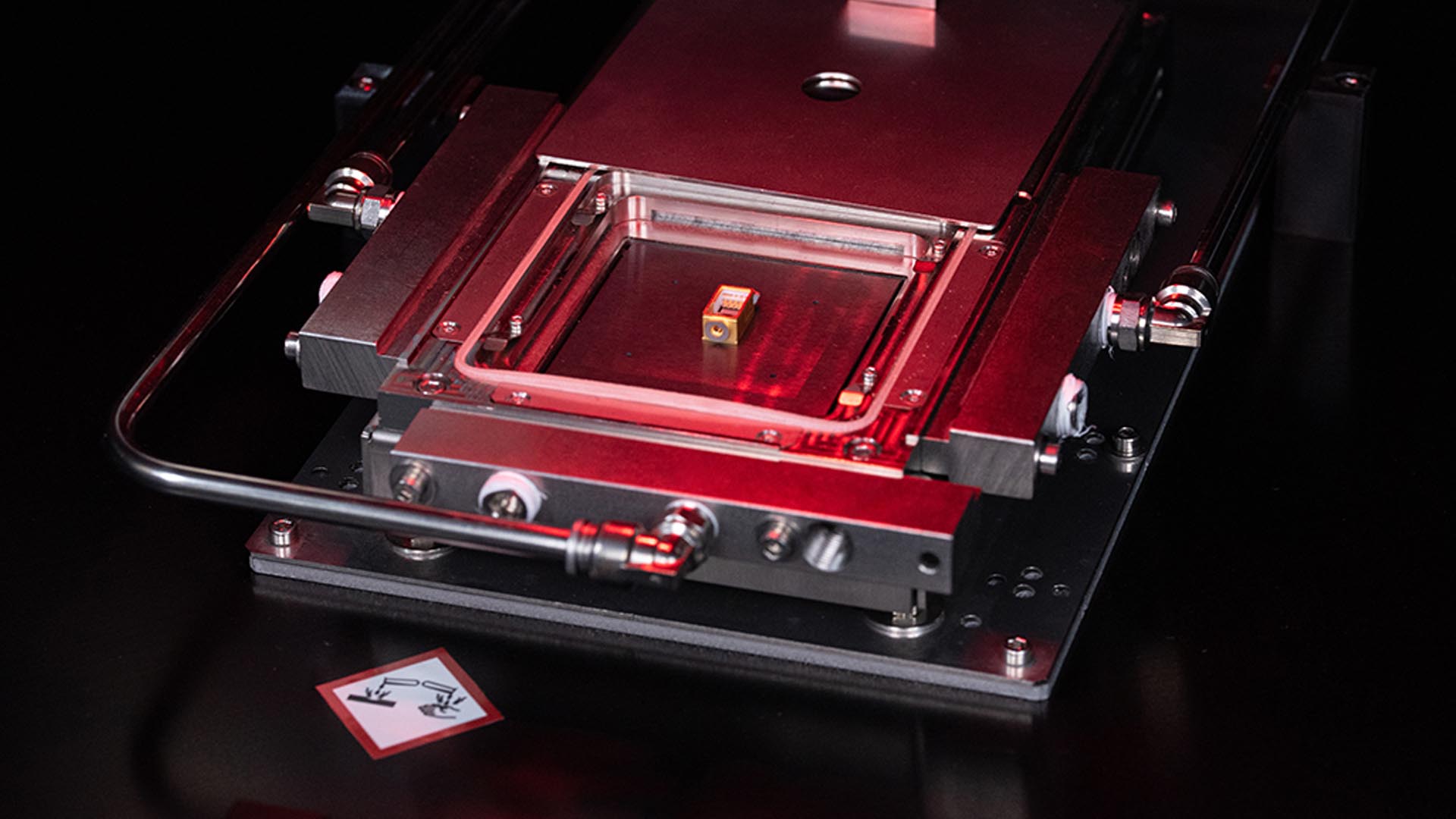

Tresky's innovation comes as an answer to these challenges. The formic acid module has been artfully crafted to be incorporated into eutectic soldering and thermocompression bonding processes, employing materials like gold-tin or indium—favored for their reliable properties in delicate bonding applications.

During the bonding process, the module meticulously enriches nitrogen with formic acid gas through an apparatus known as a bubbler. This results in a nitrogen-formic acid vapor blend, which is then precisely introduced into the process chamber. This mixture is subsequently extracted in a controlled way to ensure operator safety and optimize the formic acid's effectiveness—testament to Tresky's adherence to not only technological innovation but also stringent safety protocols.

The challenges posed by optoelectronics and photonics are myriad, notably in the fight against voids or contamination by external impurities. Formic acid steps up as a powerful ally, offering a robust reduction of oxides while concurrently sidestepping the need for flux, traditionally used in soldering but problematic in more sensitive applications.

Highlighting the economic efficiency and longstanding stability of this process, Schultze emphasizes the significant benefits that their die bonders, now integrated with the formic acid technology, offer to clients. The ability to create complex assemblies within optoelectronics marks a significant leap forward.

Through incorporating the formic acid module into its comprehensive suite of bonding solutions, Tresky demonstrates its commitment to delivering cutting-edge technologies to its customers—reliably enhancing the capabilities of industry professionals and providing innovative pathways to optimize optoelectronics manufacturing.