With the ground-breaking ceremony on September 6, 2022, construction work on the new high-tech factory (Fab) of the Jenoptik Group in the Airport Park Dresden. The two of them broke ground together with Jenoptik board members Stefan Traeger and Hans-Dieter Schumacher as well as other representatives of the photonics group. In the afternoon, the company invites its currently around 60 employees* at the site together with their families to the summer party on the construction site.

“Dresden will become a main location for our micro-optics activities. We made a conscious decision to go to one of the most important locations for the semiconductor industry in Germany and Europe, where many global companies and research institutes in the industry are based,” says Stefan Traeger, CEO of JENOPTIK AG.

Prime Minister Michael Kretschmer: “The new construction of Jenoptik's clean room factory in Dresden sends a strong signal and makes an important contribution to the further technological development of microchip production. The settlement of Jenoptik once again proves the attraction of Silicon Saxony and shows how important an existing good local network is in order to attract new companies to the location. I am pleased that Jenoptik is convinced of this semiconductor ecosystem, which is unique in Europe, and I am sure that all partners at the site will benefit from this settlement.”

“The state capital of Dresden is proud to have been supporting such an innovative and globally active East German group in its growth for years. The new Jenoptik Fab shows that Dresden offers an ecosystem with excellent research facilities, highly qualified specialists and strong partners, in which high-tech companies are constantly developing,” says Dresden Mayor Dirk Hilbert on the Jenoptik investment.

Extremely demanding construction and manufacturing environment

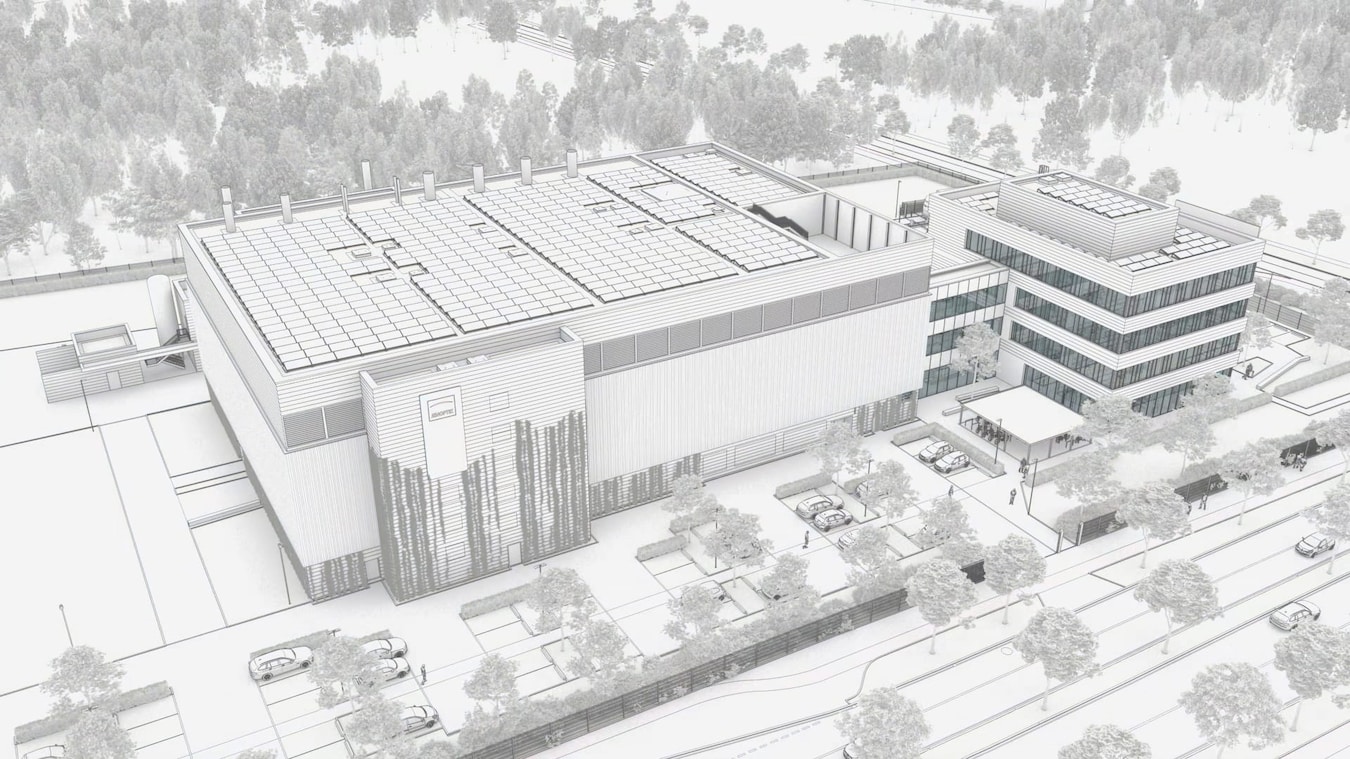

Jenoptik is investing more than 70 million euros in the new high-tech fab with a total of 11,000 square meters of net usable space, including 2,000 square meters for clean room production. The start of production is planned for early 2025. In the new high-tech fab, micro-optics and sensors are manufactured, which are mainly used in systems for semiconductor lithography. Production takes place in the two clean room classes ISO 5 and 3, which also meet the highest requirements for freedom from vibration and temperature stability. Comprehensive vibration monitoring is also in place during the construction of the fab so as not to disturb the production processes of the neighboring companies in the business park.

High environmental standards taken into account

In addition to precise production conditions, the high-tech factory also meets high environmental standards: Jenoptik strives to meet the currently most comprehensive and strictest building criteria in terms of sustainability with the "KfW 40 Standard" and the "LEED Gold Standard Certification". In order to achieve this, comprehensive, environmentally friendly measures are planned, such as a photovoltaic system, recycled materials during construction, a highly efficient building envelope including greening, cold and heat recovery and intelligent control technology.

Photonics as a growth driver

Jenoptik has been active at the Dresden location since 2007 and currently has more than 60 employees there. With the new production facility, Jenoptik will bundle production in Dresden, which is currently spread over several smaller external locations. The photonics group is thus creating 60 additional high-quality jobs and increasing the number of employees on site to a total of more than 120 employees. In addition to Dresden, Jenoptik also manufactures its high-precision and micro-optics at the Thuringian sites in Jena and Triptis (polymer optics), in Heerbrugg, Switzerland, and in Jupiter (Florida) and Huntsville (Alabama), USA. In the Advanced Photonic Solutions division, around 2,300 employees work on photonic technologies for the success of future industries.

Optics & sensors for the semiconductor equipment industry and other sectors such as medical technology & life sciences or IT infrastructure & communication are key growth drivers for Jenoptik. As a photonics group, Jenoptik is concentrating on the expansion of these business areas, from which around 75 percent of the targeted EUR 1.2 billion in sales should come in 2025. “We invest both in acquiring companies – as our most recent acquisitions show – and in organic growth, for example by expanding our own infrastructure. The high-tech factory in Dresden is the largest single investment in recent Jenoptik history,” says CFO Hans-Dieter Schumacher.

With the new fab, Jenoptik is meeting the rapidly increasing demand for photonics solutions. Industry experts predict that the semiconductor equipment industry - the main buyers of products from the new fab - will continue to grow in the coming years.

Focus on high demand for micro-optics

An important area of application for micro-optics is the semiconductor equipment industry. For example, the micro-optical sensors enable the exact positioning of the wafers during the lithographic processes for chip production. Areas of application are in both DUV and EUV lithography. Micro-optics and micro-optical sensors are characterized by the highest precision in the smallest space and a very flat design. They direct the light using micro- and nanostructures and – unlike classic optics – are manufactured using a lithography process similar to semiconductor production. In addition to chip production, they are used in other, primarily technological, manufacturing processes in which highly precise and/or very flexible positioning of light for process steps, for example in laser material processing, or quality assurance, for example in inspection processes. The very light and small individual components, often only a few micrometers in size, can be combined into miniaturized scanning and switching systems with a wide range of flexible applications.