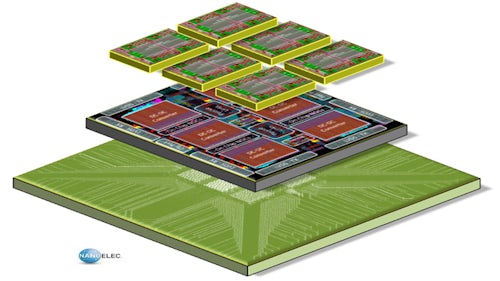

Heterogeneous Integration (HI) has enabled the development of advanced electronic systems by combining individual chiplets, each with unique capabilities, into a single chip that provides high computational performance while remaining compact. This technology has become increasingly popular as it helps to overcome challenges such as increased circuit complexity, interconnectivity, and device density.

Despite the growing popularity of HI, the lack or absence of standardized modeling practices for chiplets can lead to increased costs, design complexity, and delayed time-to-market. This can create issues for manufacturers who need to optimize the design and modification processes to develop efficient and cost-effective production processes that are optimized with the supply chain. In response to this, Siemens has released a white paper that emphasizes the importance of standardizing chiplet models to accelerate innovation and optimize the design process.

The white paper identifies four levels of model standardization, with each level building on the previous one. The first level involves model format and data structure, which helps to ensure that the data structure is consistent across all models to improve compatibility and readability. The second level involves model structure and parameter naming conventions, which standardize the modeling structure and naming conventions to enable simpler design processes. The third level involves model test parameter ranges, cases, and requirements, which ensure that the models are tested using the same set of parameters cases, and requirements. The fourth level involves model development tools, languages, and environments, ensuring that the modeling processes are compliant with a standardized set of tools, languages, and environments.

Achieving standardization in model development is essential in promoting industry-wide collaboration and optimizing the supply chain. By eliminating discrepancies in modeling practices, businesses can reduce manufacturing costs and deliver improved and reliable products. Standardized modeling practices for chip will enable the industry to meet the growing demand for high-performance electronic devices while ensuring cost-efficient and optimized production processes.

In conclusion, the white paper by Siemens highlights the importance of standardization in chiplet models to facilitate the development of advanced electronic systems. Standardization is critical in enabling businesses to optimize the design and modification processes to develop efficient and cost-effective production processes that are optimized with the supply chain. It creates consistency across the industry, improves collaboration, and ensures that manufacturers can deliver innovative and reliable products to meet the growing demand for high-performance electronic devices.

Complete document can be viewed here https://static.sw.cdn.siemens.com/siemens-disw-assets/public/5VU5kvX8I7Spha5c3DtfQB/en-US/Siemens%20SW%20Standardization%20of%20Chiplet%20Models%20for%20Heterogenous%20Integration%20White%20Paper.pdf?li_fat_id=fb554050-b3b3-4777-8db8-8e7631c0d4ed&li_fat_id=197c2721-c5df-4960-a479-6870ec83d988