Investigating novel materials for chip production and facilitating their analysis directly in the manufacturing environment are the primary objectives of two scientific teams hailing from the Brno region in the Czech Republic—the teams being comprised of researchers from Thermo Fisher Scientific and Brno University of Technology. These teams rely on electron microscopy techniques to realize their goals. Through their efforts in the European ALL2GaN project, they are working towards the development of gallium nitride (GaN) chips, which boast tremendous potential in energy conservation and mitigating the climate crisis by reducing CO2 emissions. These GaN chips are anticipated to find applications in various fields such as telecommunications and e-mobility.

The use of GaN chips in solar cells and electric car chargers is a significant development. Due to their compact size and high energy conversion efficiency, GaN chips have the capacity to deliver more energy while contributing to energy savings and innovative improvements in green technology. It is estimated that the widespread adoption of GaN chips, as envisaged in the project, could potentially save up to 218 million tons of CO2 emissions annually on a global scale.

Thermo Fisher Scientific, a leading manufacturer of electron microscopes, places great importance on sustainable design and is actively involved in delivering solutions that significantly contribute to sustainability, such as through their participation in the ALL2GaN project. Tomáš Vystavěl, a member of the Thermo Fisher Scientific development team, emphasizes the importance of green energy and suggests that if the various types of chips being developed in the project are implemented, they could potentially save around one-sixth of the world's annual electricity production from nuclear power plants.

The ALL2GaN project encompasses a wide range of applications, including telecommunications, data centers, server farms, e-mobility, renewable energy, and highly efficient smart grid solutions. Miroslav Kolíbal from the Faculty of Mechanical Engineering and CEITEC Brno University of Technology highlights the continuing research and technological challenges associated with GaN, which, if overcome, will enable the production of advanced chips at an attractive price point. The project aims to leverage this new knowledge to create components that will revolutionize the power electronics market, resulting in more efficient voltage converters, energy conversion electronics for devices like solar cells, and powerful wireless chargers for electric vehicles.

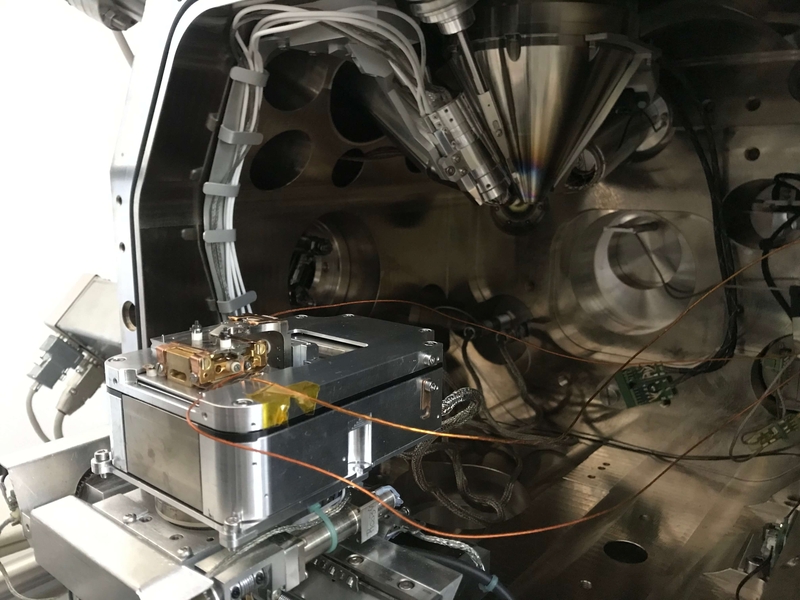

The research process for implementing these advanced chips into power electronics begins with materials research. Thermo Fisher Scientific and its development team are engaged in the analysis and development of gallium nitride substrates for chip fabrication. The material itself contains dislocations, which are line defects in the crystal lattice and can impact the chip's functionality. The team's objective is to enable chip manufacturers to work with substrates that have minimal dislocations. To achieve this, the team utilizes advanced electron microscopy techniques to observe and quantify potential defects in chips without causing damage. They employ non-destructive characterization methods, enabling crucial insights into defects and their influence on device properties.

The close collaboration between the Brno University of Technology (BUT) and Thermo Fisher Scientific is instrumental in chip development. In pursuit of this objective, the research teams prepare thin samples for observation in a transmission electron microscope, which aids in identifying the causes of chip failure. The BUT team, specialized in the physics of defects, closely collaborates with Thermo Fisher Scientific to investigate how dislocations affect the properties of GaN chips.

Contributing to the research efforts, the CEITEC Nano Research Centre, which forms part of the Brno University of Technology, provides advanced analytical techniques that support the research conducted by Thermo Fisher Scientific. The inclusion of selected analytical techniques in the production environment is a collaborative effort involving several industrial partners.

Although establishing automated and production-friendly methods is a current challenge, the aim is to set up and automate existing manual techniques. Through their contributions to the ALL2GaN project, the experts from Brno play a pivotal role in this aspect. These teams from Brno possess extensive experience and expertise in electron microscopy and the semiconductor industry, making them valuable partners in the project.

Furthermore, their involvement in the ALL2GaN project further bolsters the region's reputation for cutting-edge research bridging electron microscopy and the semiconductor industry. This collaboration holds the potential to establish Europe as a leading force in power electronics, thus distinguishing it from logic circuits in processors and solidifying its position in the semiconductor industry. The region of Brno, where the National Competence Centre for Chips activities are coordinated, actively contributes to these advancements.

The ALL2GaN project, titled "Affordable smart GaN IC solutions for greener applications," focuses on the development of easily integrated, energy-efficient gallium nitride chips. These chips have the potential to increase energy efficiency by up to 30% in a wide range of applications, including mobile device charging, data center power supply, residential voltage converters, and on-board chargers for electric vehicles. If implemented globally, this technology could potentially save up to 218 million tons of CO2 emissions. The project, led by Infineon Austria and featuring 45 partners from 12 countries with a budget of around €60 million between March 2023 and April 2026.