Kulicke & Soffa (NASDAQ: KLIC) is a leading provider of semiconductor and electronic assembly solutions serving the global automotive, consumer, communications, computing and industrial markets. Founded in 1951, K&S prides itself on establishing foundations for technological advancement - creating pioneering interconnect solutions that enable performance improvements, power efficiency, form-factor reductions and assembly excellence of current and next-generation semiconductor devices.

Leveraging decades of development proficiency and extensive process technology expertise, Kulicke & Soffa’s expanding portfolio provides equipment solutions, aftermarket products and services supporting a comprehensive set of interconnect technologies including wire bonding, advanced packaging, lithography, and electronics assembly. Dedicated to empowering technological discovery, always, K&S collaborates with customers and technology partners to push the boundaries of possibility, enabling a smarter future.

ADVANCED PACKAGING WITH ADAPTIVE MACHINE ANALYTICS - MORE THAN BONDING

As features and functionalities of ICs increases, driving higher I/Os, the trend for flip chip is moving towards pitches less than 100 μm needing higher accuracy flip chip bonding and alternative interconnect solutions. Designed with performance and accuracy in mind, K&S APAMA™ Plus Thermo-Compression Bonding (TCB) solutions provide higher accuracy and lower pitch bonding with market leading throughput.

The APAMA Series offers fully Automated Chip-to-Substrate (C2S) and Chip-to-Wafer (C2W) solutions for Thermo-Compression Bonding (TCB).

HIGHEST ACCURACY, HIGHEST UPH FLIP-CHIP PERFORMANCE

Kulicke & Soffa's Katalyst™ delivers the industry's highest accuracy and speed for flip-chip placement. Its hardware and technology enable < 3 μm accuracy on substrate or wafer, achieving the best Cost-of-Ownership in the industry.

Key Features:

- Best-in-industry flip-chip at 15K UPH Sprint with 3 μm accuracy

- Ease-of-use Automated Recipe with fully guided Setup Wizards

- Automated , UPH neutral Accuracy Calibration, to avoid nozzle-to-nozzle variations during runtime

- Automated thermal Drift Compensation

Wafer Level Packaging (WLP)

- Bonding Flip Chips and/or Passives onto wafers or panels

- Processing wafers sizes up to 12" and larger

- Cam-X and Secs-Gem compatible

- Feeding from wafer, waffle pack, tray or tape and reel

- Full controlled Placement force for thin Flip Chips or low profile passives

- Full traceability

- Fine pitch Copper Pillar Bumps

MCM & SIP/FC BGA/FC-CSP/ FC-Memory/FCOB

- Up to 27,000 cph (IPC) Flip Chip bonding speeds

- Up to 140,000 cph (IPC) Chip shooting speeds

- High quality pick and placement process

- 7 Micron for Flips Chips, Die and Wafer Level Packages

- Full controlled Placement force for thin Flip Chips or low profile passives

- Feeding from wafer, waffle pack, tray or tape and reel

POP (Package-on-Package)

- Die or BGA stacking at the highest throughput on smallest footprint

- Feeding from wafer, waffle pack, tray or tape and reel

- Full force control with every Placement at all placement height

- Easy to exchange linear flux unit

Kulicke & Soffa's ball bonders are the leading generation of semiconductor assembly equipment for today's most challenging applications. With our long-standing tradition of innovation and technology leadership, the K&S ball bonders set new standards for performance, productivity, reliability, and ease of use.

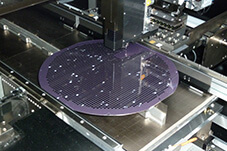

K&S Lithography brings you a breakthrough in Lithography for Advanced Packaging by developing a dedicated solution with a major reduction in Cost-of-Ownership.

Key Features & Benefits of the LITEQ 500 projection stepper

- Highest Throughput

- Up to 2x better Cost of Ownership

- Laser based light source

- Innovative optical design

- High speed wafer handling

- Modular system architecture

- Differentiating software